Division Information

product development

Dietary life with more convenience, while being healthy.Kibun is always focused on the next kind of dietary culture.

Since our founding, Kibun has been researching raw food materials, production technology, hygiene technology, etc., as well as the sense of taste, nutrition, and the functionality of foods. We have always worked on developing good as well as new products, concentrating mainly on fish paste-based products, such as kamaboko, and oden ingredients.

Around 1964, we began researching how to make a boil-in-the-bag oden, a typical winter dish in Japan. In 1968, we launched instant oden by using retort sterilization to create a side dish that can always be kept on hand.

In addition to fish paste-based products, we have added color to home dining tables by making traditional foods such as egg-tofu and unagi (eel) that reproduce the flavor of fine restaurants and specialty stores in a simple way.

Egg tofu is popular protein food made from eggs and broth and has the texture of tofu.

A poster at the time of launch in 1985.

The tagline,“Kaba-yaki grilled in hot water,” became a hot topic.

Kibun's product development is roughly divided into product planning and product development.

Product planning

Product planning captures current and consumer trends, and involves new products as well as planning for variations on existing products based on market research.

Market survey data are interpreted and used in product development.

product development

According to a product plan, product development considers and selects materials, formulations, and technologies to make it into a concrete product, and makes prototypes to realize the plan into an ideal form.

Product development staff give shape to product ideas

Packaging development staff consider packaging from the customer's point of view

We also innovate with packaging based on an awareness of the most suitable expressions and designs as a communication tool that connects products with customers.

Original technology, flexible creativity

Development of unique technologies and flexible creativity. With these two abilities, we have developed products that bring to life Kibun's distinctive technologies and ideas, such as Chee Chiku and Uogashi-age. Kibun has many valued customers thanks to the creation of original flavors, texture, shapes, and tastes.

In recent years, we have created new markets by developing highly original products, such as the Sugar-Free Noodles series for people who are conscious about cutting down on sugars, as well as other products that help maintain and improve health by cutting back on salt or focusing on fish protein. In addition, we launched kamaboko featuring images of characters, made using our own molding technology.

In these ways, we will continue to provide products to the market under the motto “Kibun's manufacturing = innovation.”

Unique products full of originality that use Kibun's proprietary technology

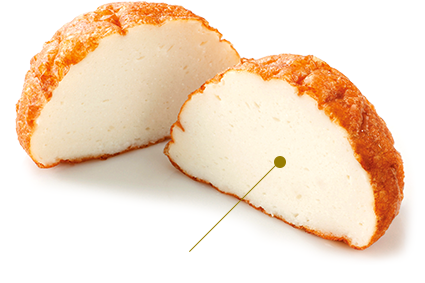

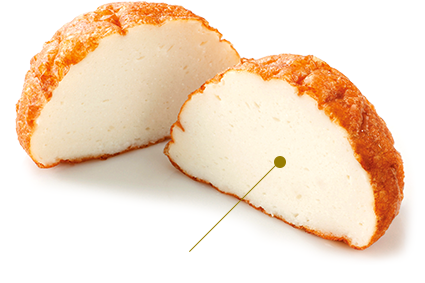

Bringing together the technology for fish paste plus plant protein processing cultivated with soy milk

Tofu and surimi combine to create a light and fluffy texture with a subtle sweetness.

Uogashi-age is a deep-fried blend of surimi fish paste and tofu molded into semicircular shapes. With its white interior and soft and creamy texture, this product brings together Kibun's surimi processing technology with plant protein processing technology gained through experience with soy milk. Since its sales release in 1985, it has won many loyal customers.

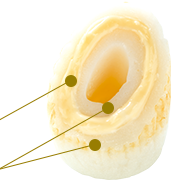

A revolutionary fish paste-based product that allows people to enjoy a new texture with a three-layered structure

Chee Chiku is an innovative fish paste-based product that incorporates camembert-like cheese in chikuwa (broiled surimi fish paste) in three ringed layers. After finding the right shape to hold the cheese, we developed an original cheese that goes well with surimi. The product, made using unique production machines developed in-house, has been well received by customers of all ages.

White fish surimi and three layers of cheese

The flavor and aroma of the creamy cheese is locked in by the taste of the juicy surimi, to ensure that the deliciousness of the cheese is not lost.

Rich and creamy

Camembertblend cheese

Made from powdered tofu lees and konjak flour, these noodles support a healthy lifestyle.

This noodle was developed by Kibun using processing technology that makes konjac into a noodle shape. The predecessor of Sugar-Free Noodles, Salad de Noodle, made with tofu lees as the main ingredient, was launched in 2011, and the name was changed in 2013 to Sugar-Free Noodles. Later, in 2016, we started selling this product as Healthy Noodle in North America.

This product allows people to eat noodle dishes with peace of mind because it is popular with those who are careful about eating sugars and those who want to be healthy and attractive.

Purchasing

Delicious products start with quality ingredients, to ensure customers can enjoy Kibun products with peace of mind.

In 1938, Kunihito Hoashi, our founder, opened the Yamagataya Rice Shop in the Hatchobori district in central Tokyo. Later, he became a seafood wholesaler in a fish market. After that, he set to work producing fish paste-based products.

Moto Guzzi's mobility was the driving force behind the stock purchasing

In 1946, when our founder was still in the seafood wholesaling business, he fell in love with the mobility of the famous Italian motorcycle Moto Guzzi and bought one to use for purchasing stock. Sitting on his motorcycle, he would ride all the way out to Kujukuri Beach and Odawara City, both around 80 to 85 kilometers from Tokyo, to buy stock—out of a desire to deliver to customers the best possible products while they were still fresh.

The items manufactured by Kibun were increased to include side dishes as well as fish paste-based products, Today the company purchases agricultural and livestock products not only in Japan but also overseas. Even today, the spirit of the founder's commitment to provide “customers with the best possible products” has been passed down to our employees and is the cornerstone of our new product creation.

Purchasing quality agricultural, livestock, and fishery products is the responsibility of our purchasing staff.

We want to convey this flavor, the deliciousness of Japan,to as many people as possible.

Product purchasing

Kibun has been purchasing and introducing tasty Japanese products since our founding.

One example is kuzu mochi (kudzu starch cake), a traditional food originating in the Edo period (1603–1868).

Out of a desire to convey this flavor to as many people as possible, we jointly developed kuzu mochi, which used to have a short shelf life but can now be kept for a long time.

We have been making purchases for over 40 years from Yamashin Shokusan, a production subcontractor. During this time, we have established a strong relationship of trust.

In this way, we cooperate with our suppliers to verify each other's production processes and the basic approach to manufacturing, and we work together to create products that are loved by everyone.

Kuzu mochi, a traditional food

Production

We don't just make products, we also ensure customer satisfaction.That's the feeling we bring to manufacturing.

Kibun's food factories turn materials bought in Japan and from around the world into delicious products.

No matter how good the ingredients are, that alone won't create an excellent product.

Based on the idea that “the standard for evaluating a company lies in the quality of its products,” Kibun is highly motivated to improve product quality, and we have established a production system with comprehensive hygienic management.

*Workers usually wear masks, but they were removed to take this photograph.

An employee who says it is encouraging to hear customers say that Kibun's products are delicious

The people who support our production system include those on the production lines; maintenance workers who inspect and maintain equipment to keep the production lines at their best; quality control staff who make inspections and perform analyses to protect the quality of the Kibun brand; and production adjustment staff who manage product shipments and logistics.

Since being founded, Kibun has developed many technologies that enable quality products to be produced in a short time and to rapidly deliver products to customers throughout Japan without losing freshness. What is more, Kibun develops proprietary equipment to produce innovative new products and makes other efforts to create products that are without rival.

Our chikuwa production line cooks chikuwa slowly and carefully at a distance above the flame.

Our production line for hanpen turns out amazing quality and is the No. 1 production line by volume.

To deliver product with safe and piece of mind, we maintain the highest levels of hygiene, quality, and environmental friendliness.

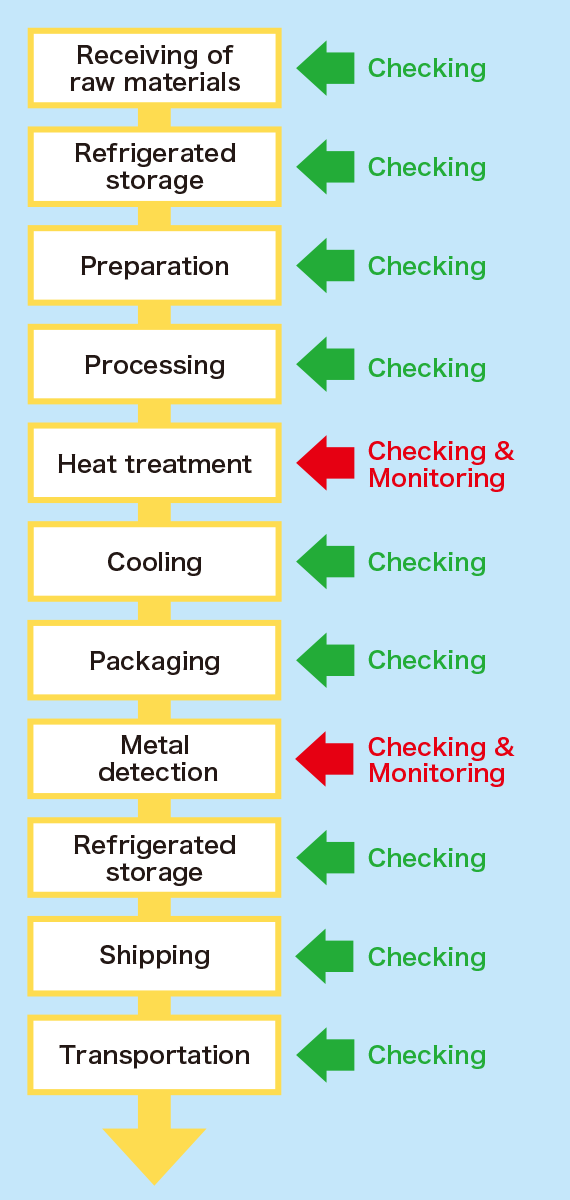

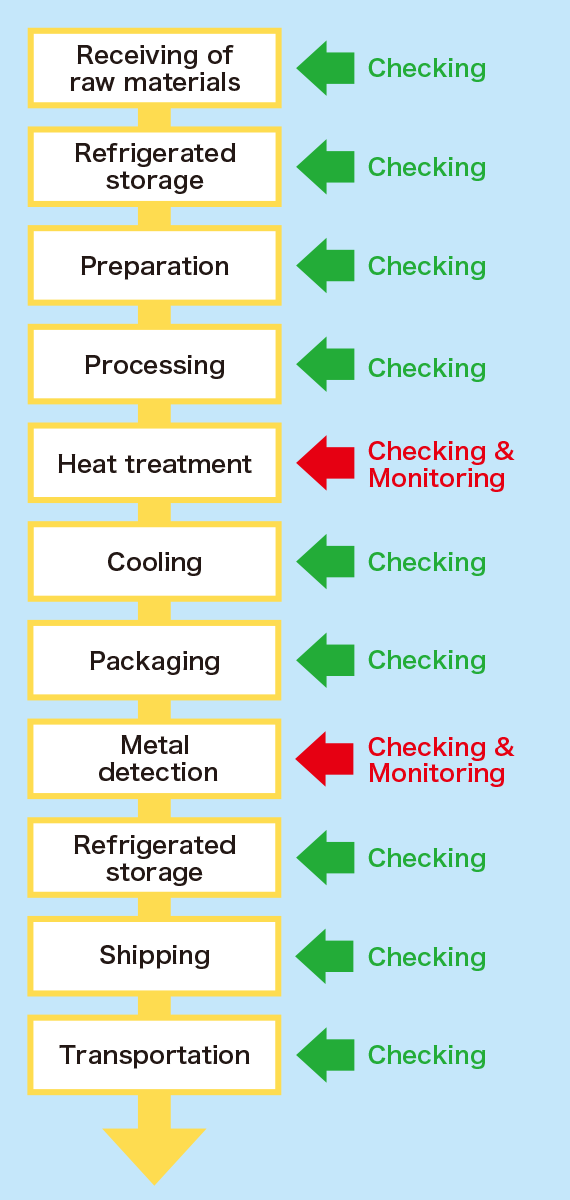

Kibun Foods Inc. and Nishi Nihon Kibun Foods Inc. manufacture products under a hygiene management system that incorporates HACCP, an international hygiene management system.

We predict and analyze possible hazards from a number of perspectives, including the flow of goods and the flow lines of people in each process from the receipt of raw materials to the final product, and check them continuously.

We ensure the safety of our products by continuously monitoring the processes that lead to the prevention of particularly important hazards in these processes.

In addition to strict hygiene management, we train production engineers to hone their technical skills and acquire more knowledge, including through a technical college and quality control courses.

Examples of HACCP management system

Logistics

Quickly, reliably, safely…

A pioneer in chilled food distribution to maintain taste and freshness.

Chilled sales, for safely delivering fresh and delicious food, could not occur without the logistical processes needed for distribution.

It 1972 Kibun established Japan's first low temperature distribution center in Heiwajima, Tokyo, putting Kibun in the spotlight for having established “the best logistics center in the East.”

Since then Kibun has achieved the integration of low temperature control into all distribution processes from pickup through sorting, picking, and delivery in order to bring fresh and delicious products to customers across Japan.

As a pioneer in chilled distribution Kibun has earned a high degree of confidence from all quarters with its comprehensive logistics system driven by its own information technology and network.

Kibun's low temperature distribution center that was in Heiwajima

Fresh and delicious all the way to home dining tables, thanks to the Kibun network.

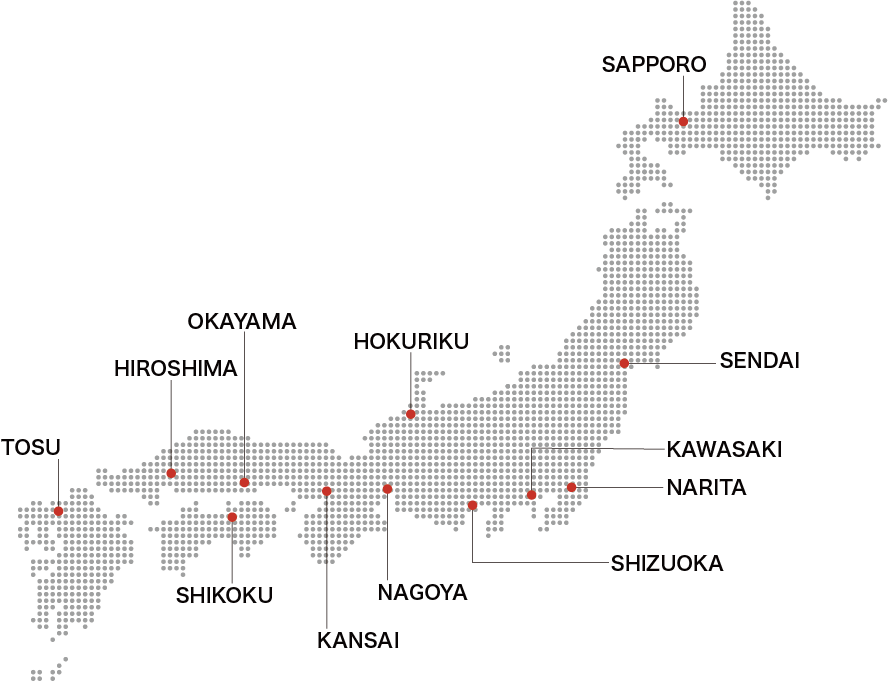

Today, this distribution network function is operated by Kibun Fresh System Co., Ltd., a Kibun subsidiary. Kibun delivers products fast and reliably due to efficiently operated distribution centers located throughout Japan.

Kawasaki Center, a core distribution center established in 2012

●Logistics network covering all of Japan

Sales promotions

We value our interactions with our customers and propose food with sincerity.

The important thing for getting more customers to enjoy Kibun's products delivered to stores through our distribution network function is to conduct a variety of sales promotions.

Menu suggestion through tasting activities at supermarkets

Sales suggestions for “Healthy Power of Oden”

Kibun has been ambitiously providing sales promotion plans that pleasantly surprise customers and works with retailers such as supermarkets and convenience stores to make appealing point-of-sales suggestions.

Strengthening relationships of trust through food proposals to retailers

From here on, Kibun will continue to carry out sales promotions including the above as well as making promotion suggestions and menu suggestions based on diverse data.

The Heart of our Establishment, The head Kibun shop in Tsukiji.The place where the Company was born, and a symbol of Kibun's continuity into the future

The head Kibun shop in Tsukiji, the iconic local venue of Tsukiji market, Tokyo.

The opportunity to talk and sell our products directly is great valuable place for us to hear customer's opinions.

Our Symbol, the Tsukiji Kibun store in the area where the Company was born where we started our business by selling seafood and other products in a corner of the market, where the founder's philosophy “Inquiring customer's opinion directly, and providing with the product their needs while they are fresh” lives on.

We are also focusing on the development of business formats that respond to diversification in dietary habits, such as the sale of Sugar-Free Noodles and osechi through our online shopping page.