Providing safe food that brings peace of mind

Ensuring food safety and customer confidence with comprehensive hygienic management

Kibun's approach to quality and hygienic management

Kibun has strengthened its production controls and quality and hygienic management, making safety the highest priority so that customers can enjoy Kibun products with peace of mind.

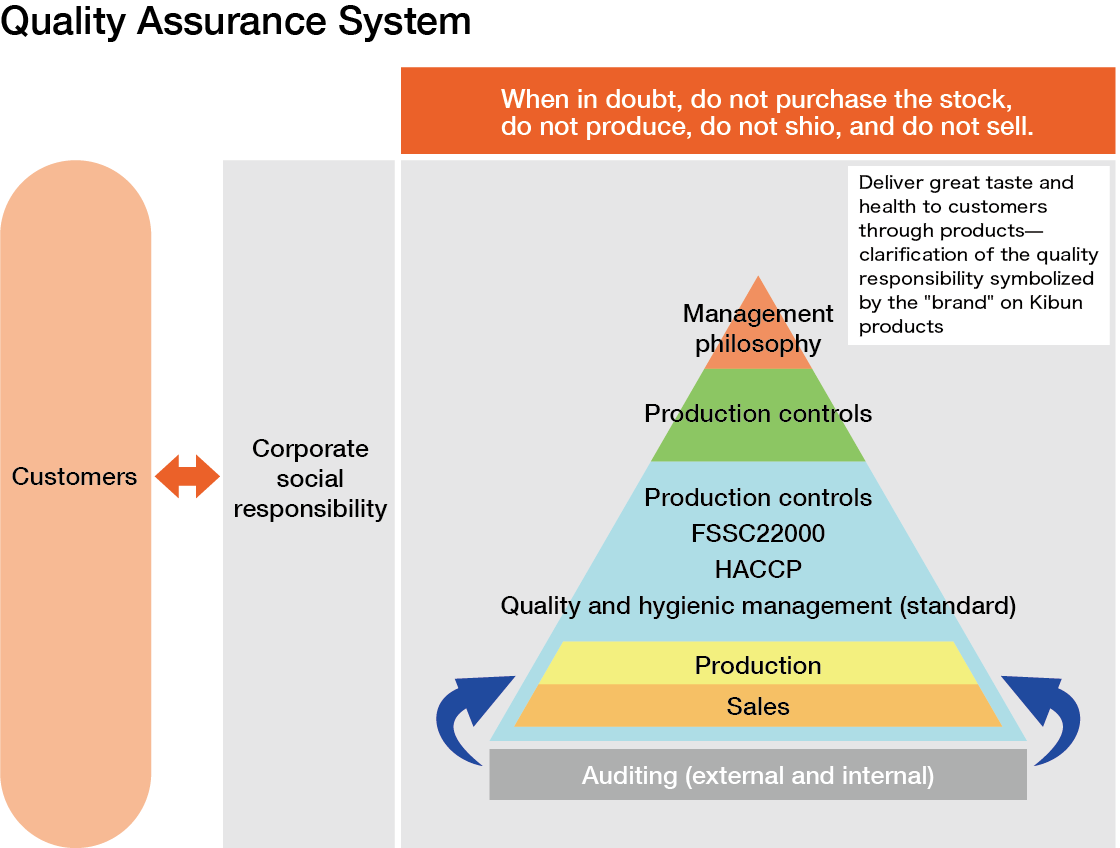

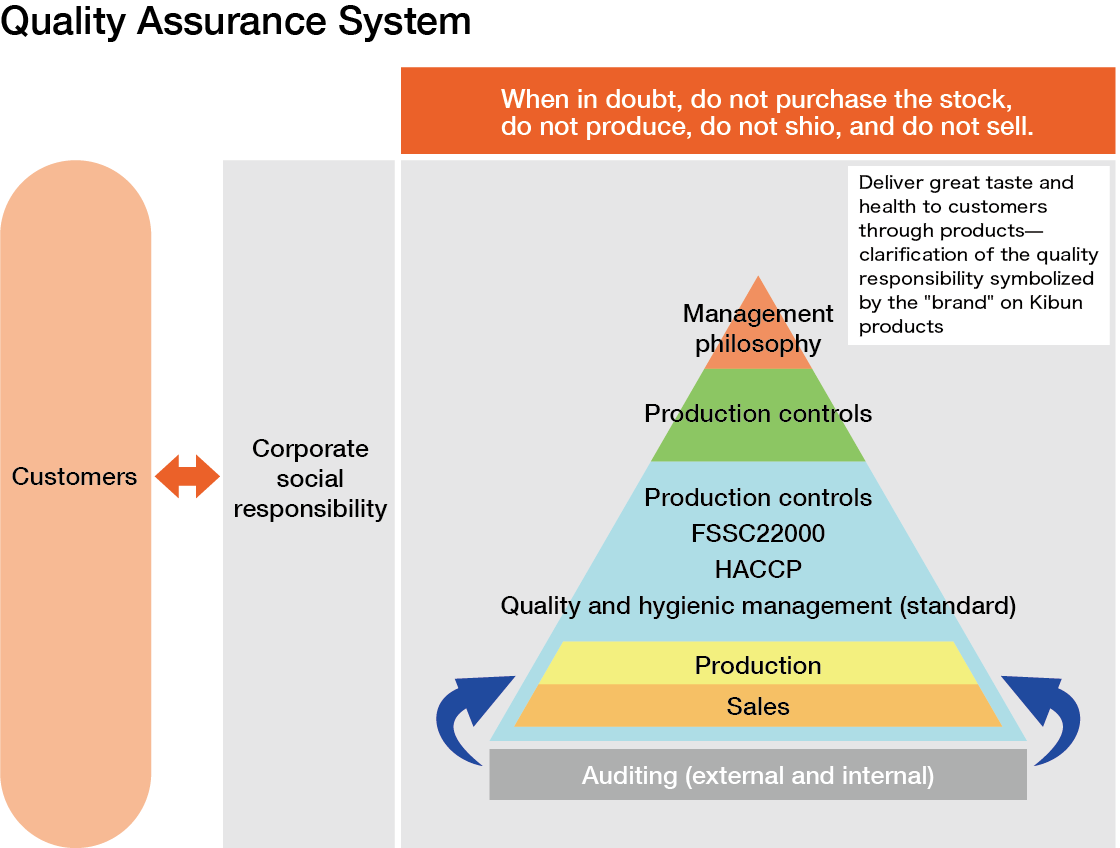

“When in doubt, do not purchase the stock, do not produce, do not ship, and do not sell.” Based on the manufacturing philosophy of Kibun, we have instilled an awareness of food safety in each and every employee.

The Kibun Foods Safety Center Inc., established in 2016, specializes in pursuing “food safety and peace of mind.” The center inspects, analyzes, and consults on quality and hygiene within the Kibun Group. This structure helps Kibun meet the rising expectations of customers for food safety and customer confidence.

Quality assurance system

Staff at our center carry out careful quality assurance inspections.

Analyzing product composition

Recoding analysis results

Quality and hygienic management

The Hazard Analysis and Critical Control Point (HACCP) system has been introduced at all factories of Kibun Foods Inc., resulting in FSSC 22000 certification for the Company's food safety management system.

Kibun's Tokyo Factory, Yokohama Factory and Okayama Soja Factory have also received accreditation from the United States and European Union as facilities exporting food to those destinations.

Metal detectors are installed on all lines based on hazard analysis.

Comprehensive quality management activities take place every day, without fall

The Kibun Foods Safety Center has obtained ISO/IEC 17025:2017 certification, an international standard that recognizes a laboratory's ability to produce internationally accepted and verified test results for inspections, analyses, and measurements.

Factory quality management

In a product quality control office at each factory, Kibun inspects the quality of all products, and checks and confirms the product line each day. As an example, in our specimen laboratories we test the preservation of each product that is stored to check the expiration date. In addition, we conduct a range of tests on each product on the production line as part of food safety and quality control.

Quality inspection room

Factory hygiene management

Employees must pass through an air shower to reach the production floor

Each factory conducts hygiene management from a number of perspectives, including the flow of goods and the flow lines of people, in accordance with HACCP certification. Inside the production space, hygiene areas are split into zones, with a management system set up for each. Thorough efforts are made with regard to hygiene management at each location, such as controlling the admission of workers so that dust, hair, bacteria and other items do not enter the production space, and installing equipment that supplies clean air.

Employee education

Hygiene management education

Twice a year, all employees are given basic education to deepen their understanding of hygiene, such as thorough handwashing. As well, they are provided information on viruses and other health management issues.

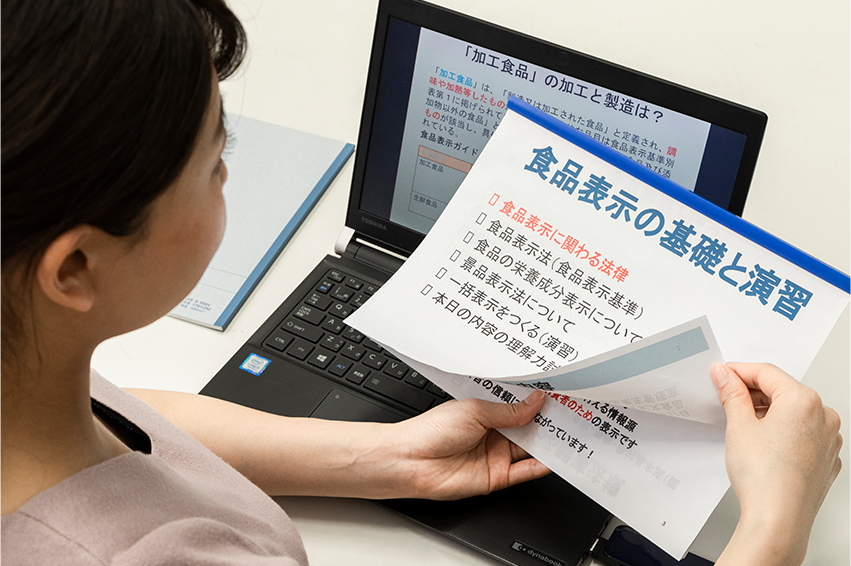

Quality assurance education

Depending on the workplace and a person's responsibilities, we provide education on food-related laws and regulations, such as labeling, and make sure all food plant employees are familiar with HACCP (hazard analysis and critical control points).

Hygiene education for all employees

Education on food-related laws and regulations